When it comes to centrifuges, there are two main types: floor centrifuges and benchtop centrifuges. In this article, we will focus on floor centrifuges, also known as floor-standing centrifuges or floor model centrifuges.

In a laboratory with limited space where placing a benchtop centrifuge on a table is not feasible, a floor-standing centrifuge becomes the ideal choice. Additionally, if your laboratory has a large number of personnel with diverse research directions and various operations, a floor centrifuge can cater to your specific needs. These centrifuges find applications in areas such as biochemistry, radio-immunity, and pharmaceutical research.

Let's explore the advantages of floor model centrifuges:

Large Capacity:

Floor centrifuges offer a larger internal space, allowing for a better selection of parts and materials, and overall stronger stability.

Enhanced Stability:

The main engine of a floor model centrifuge exhibits excellent stability, thanks to the robust design and quality materials used.

Improved Heat Dissipation:

Floor centrifuges adopt an upper and lower structure, resulting in a larger heat dissipation area. The cooling system is designed to be more efficient, reducing the chances of system failures.

Higher Unbalance Tolerance:

Floor model centrifuges are equipped with superior shock-absorbing suspension systems, providing higher stability and the ability to handle larger amounts of unbalance.

Currently, floor-standing centrifuges on the market can be categorized into three types: high-speed, ultra-speed, and low-speed centrifuges.

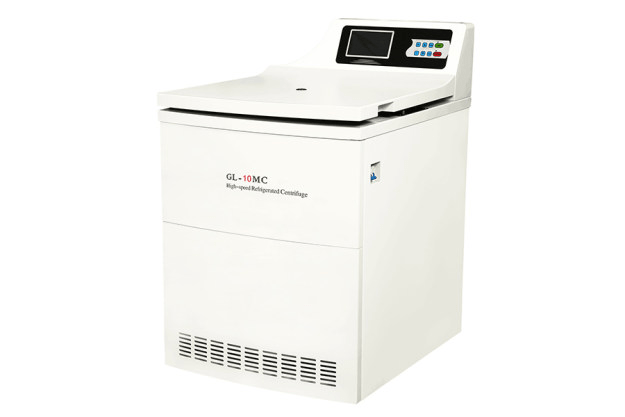

High-speed Floor Centrifuge:

For those in need of a high-capacity, high-speed centrifuge with versatility, a high-speed floor centrifuge is the optimal choice. Many high-speed floor centrifuges offer a wide range of rotors for various operations, including cell separation, protein precipitation, tissue culture, subcellular separations, nucleic acid purification, and more.

Ultra-speed Floor Centrifuge:

When applications require centrifugal forces of up to 1,000,000x g, an ultracentrifuge is necessary. Ultracentrifuges are commonly used for isolating virus particles, fractionating DNA, RNA, or proteins, lipoprotein surfacing, density gradient centrifugation, handling nanoparticles, and other advanced procedures.

Low-speed Floor Centrifuge:

These centrifuges have a maximum relative centrifugal force of approximately 7000 x g and are suitable for low-speed applications like separating red blood cells and platelets from whole blood.

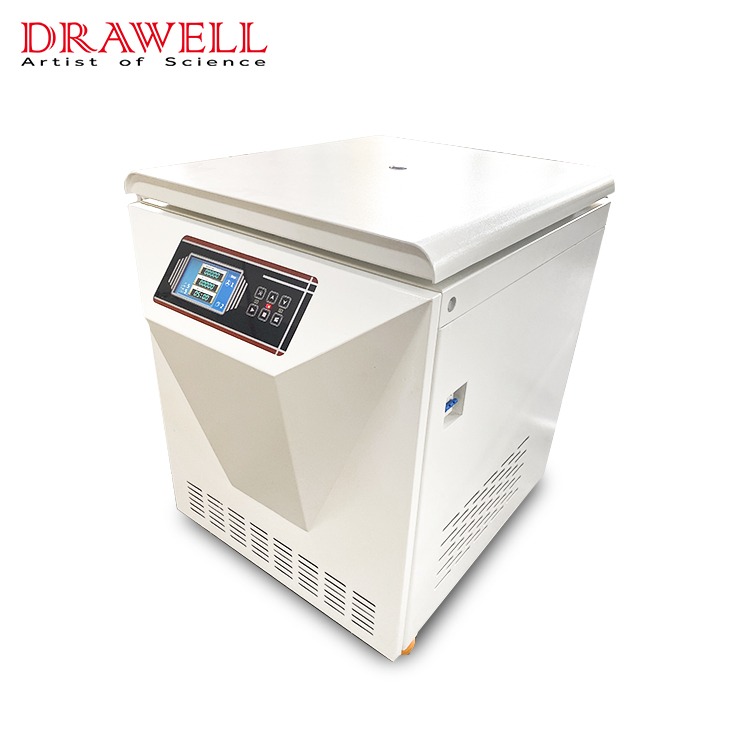

Recommended Floor Centrifuge: Floor Ultra Capacity Centrifuge

The floor ultra capacity centrifuge is a large-capacity standing centrifuge suitable for a wide range of applications. It finds extensive use in central blood stations, pharmaceuticals, bioengineering, clinical medicine, genetic engineering, hospitals, universities, blood stations, radioimmunization, nuclear medicine, and other fields. This centrifuge offers the same advantages mentioned above, along with an attractive appearance and low noise levels.

Supplier Recommendation: Drawell

For those interested in the floor ultra capacity centrifuge, Drawell is a trusted choice. With over 20 years of experience in centrifuge production, Drawell has earned a reputation for producing stable, high-quality centrifuges that are user-friendly. In addition to floor centrifuges, Drawell also offers benchtop low-speed centrifuges, benchtop high-speed centrifuges, benchtop refrigerated centrifuges, and beauty centrifuges.

In conclusion, floor centrifuges provide an excellent solution for laboratories with limited space. They offer large capacity, enhanced stability, improved heat dissipation, and higher unbalance tolerance. Whether you require a high-speed, ultra-speed, or low-speed centrifuge, a floor model can meet your specific needs. For reliable floor centrifuges and other types of centrifuges, Drawell is a trusted supplier with a proven track record in the industry.